Fastening with vertical Omega profile K20

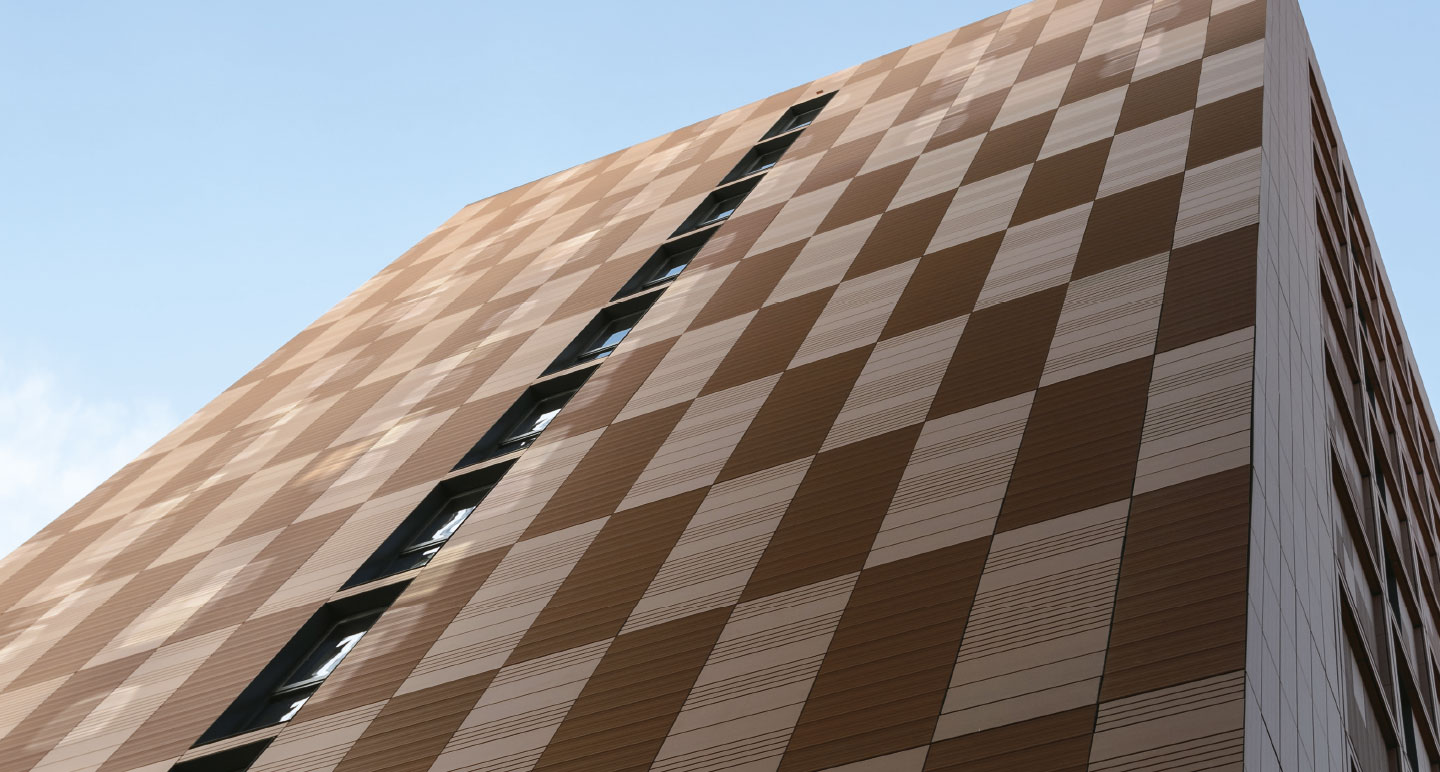

System description

The Omega profile stands out due to its simple and efficient installation on difficult bases such as e.g. walls with post and beam construction. Horizontal bearing profiles are fixed at the posts. The vertical Omega profiles can then be arranged independent of the distance between the posts, and the panel lengths can be freely planned. The complex system structure with dowel, wall bracket and vertical bearing profile is not required. The subsequent laying of the ceramics is carried out as in the case of the system rail K20. The KeraTwin® K20 facade panels are simply hung in the vertical Omega profile with the holding grooves on the reverse side. No additional tools are required for mounting the panels. The compression spring and removal protection integrated in the Omega profile prevents clattering and constraining forces in the case of alternating wind loads and also the easy removal of panels. The position of the panels is secured either by means of a joint profile adjusted to the joint width or by means of spacers.

- Facade panel KeraTwin® K20

- Vertical Omega profile K20, article 624

- A4 stainless steel screw, article 659 (alternatively, fastening with Al blind rivet, article 658, is possible)

- Horizontal bearing profile (basic substructure)

- Pay attention to profile butt joint!

- A profile butt joint of the vertical bearing profiles behind a panel is not allowed! See standard technical detail drawings.

Mounting instructions for KeraTwin® K20 – Fastening by means of vertical Omega profile K20

Substructure

The mounting of the substructure must be carried out according to project-specific, static calculation. The general approval Z-10.3-844 of the construction supervisory authority serves as basis.

- The profiles of the basic substructure have to be mounted perpendicularly and in a flush way (top-hat or alternatively Z-profile).

- The Omega profiles K20 (Art. no. 624, 627, 633) have to be precisely aligned horizontally and be fixed through the long holes provided on the edge by means of screws (Art. no. 659) or rivets (Art. no. 658). (Pay attention to fixed and sliding point execution!)

- The distance of the rails in horizontal direction must correspond to the longitudinal grid of the panels.

- A profile butt joint behind a panel is not allowed.

- In case of open vertical joints, one joint spacer per panel (Art. no. 645) is inserted in a centric extrusion hole of the panel.

- In case of closed vertical joints, the joint profile (Art. no. 640 in case of single-span girder; plug-in joint profile, Art. no. 647, in case of single-span girder with jibs) must be used.

Accessories

- * legally protected

- Profile lengths available:

- Grid 15 cm, 60 cm: 2992 mmGrid 17,5 cm: 2967 mm · Grid 20 cm, 25 cm, 30 cm, 37,5 cm, 50 cm: 2992 mmGrid 22,5 cm, 32,5 cm: 2917 mm · Grid 27,5 cm: 3017 mmGrid 35 cm, 40 cm: 2792 mm · Grid 55 cm: 3292 mmGrid 45 cm: 2692 mm

Omega profile K20 available for panel grids of 15 cm - 17,5 cm - 20 cm - 22,5 cm - 25 cm - 27,5 cm - 30 cm - 32,5 cm - 35 cm - 37,5 cm - 40 cm - 45 cm - 50 cm - 55 cm - 60 cm. Other grids on request.

Important: The use of silicone caoutchoucs must be absolutely avoided, because silicone fluids segregate and effect sticky surfaces on which dirt adheres. Therefore, only use the system components mentioned (foamed pieces, EDPM rubber profile, neoprene rubber washer) and pointing, bonding and sealing materials recommended by us. We will be pleased to inform you in detail. The usual final cleaning after completion of the construction works is still required. A warranty for the system KeraTwin® K20 in the scope of the general approval no. Z-10.3-844 of the construction supervisory authority only applies if the system components shown on these pages are used.